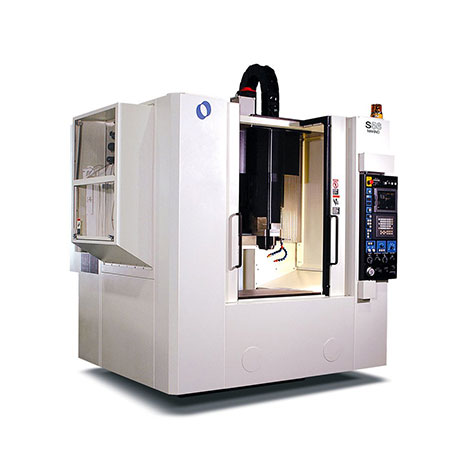

Makino S56

| Max. X travels | 900 mm |

| Max. Y travels | 500 mm |

| Max. Z travels | 450 mm |

| No. of Axis | 3 + 2 |

| Max. table load | 1,100 lbs |

| Table Size | 1000 x 500 mm |

| Speed range | 18,000 rpm |

| Country of Origin | Japan |

Makino’s new S56-5XR vertical machining center blends high-performance, hardmilling with multi-axis capabilities for the perfect combination of accuracy, speed, flexibility and productivity. Similar to the S56, the S56-5XR is perfectly suited for applications requiring high spindle speeds, fine surface finishes and hardmilling. The machine’s five-axis functionality delivers exacting accuracy in contoured parts, and enables five-face machining that eliminates set-ups, reduces lead times, improves quality, and cuts costs.

The S56-5XR is designed to assist manufacturers looking to win high-tech, full five axis, contouring jobs in a variety of markets,” says Bill Howard, Makino’s vertical machining center product manager. “Whether running simultaneous or ‘2+3’ programming, the machine provides the high speed and accuracy necessary to get the job done in the lowest cycle times possible with superb surface finishes and tight tolerances.

The S56-5XR is equipped with a 40 x 20 inches (1,000 x 500 mm) worktable, with associated travels of 36 x 20 x 18 inches (900 x 500 x 450 mm). Its table mounted tilt / trunion provides full, five-axis capability while the remaining table surface can be used for three axis work.

The machine’s X-, Y- and Z-axis linear motion guides support rapid traverse and cutting feed rates of 1,575 ipm (40,000 mm/min). Its 40 taper, 13,000-rpm spindle provides the ideal combination of speed and rigidity to hardmill high quality surface finishes in demanding applications. As an option, the S56-5XR can be equipped with a 20,000-rpm spindle featuring Makino’s patented spindle technology for further productivity.

The machine is equipped with a standard 20-tool (30-tool optional) magazine and automatic tool changer to reduce setups and further maximize the machine’s flexibility and utilization, through unattended machining capabilities.